Nozzles in the Paper Industry

The paper industry needs various technologies to increase efficiency, improve quality, and reduce costs in its production processes. Among these technologies, nozzles play a vital role. Nozzles are used in paper production to spray liquids such as water, chemicals, dyes, and the like accurately and efficiently. Below is detailed information about the types of nozzles commonly used in the paper industry, their functions, and technical data.

Types of Nozzles Used in the Paper Industry and Their Application Areas

1. Coating Nozzles

Application Area: Used to apply an even coating to paper surfaces. These nozzles are ideal for applying a thin layer of paint to the surface of the paper, in particular.

Types: Flat jet nozzles, conical fan nozzles, spiral nozzles.

Features:*

Atomization Type: Fine mist atomization (by separating the liquid into small droplets, it provides more efficient coating).

Exit Angle: Exit angles varying between 60° - 120°.

Flow Rate: 1 L/min – 50 L/min (varies depending on liquid flow).

Pressure: Between 2 bar – 6 bar.

2. Cooling Nozzles

Application Area: Used in paper machines where heat needs to be controlled. It is important to maintain the quality of the paper and prevent overheating during the production process.

Types: Nozzles that perform fine mist atomization.

Features:*

Atomization: Fine mist atomization.

Liquid Intake Capacity: 0.5 L/min – 20 L/min.

Operating Pressure: 3 bar – 8 bar.

Temperature Resistance: Between -20°C and 80°C.

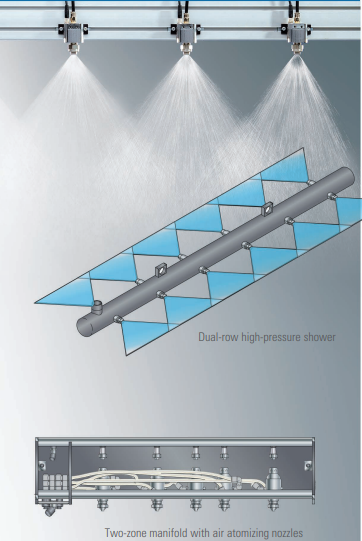

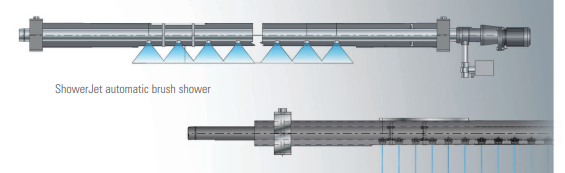

3. Washing Nozzles

Application Area: Used during the cleaning of machines used in paper production, especially on surfaces that need to be cleaned from paper fibers or dirt in the machines.

Types: Flat jet nozzles, fan nozzles.

Features:*

Flow Rate: 5 L/min – 50 L/min.

Pressure: 3 bar – 10 bar (high pressure is required to increase washing efficiency).

Spray Surface: Flat fan, round fan.

4. Water Spray Nozzles

Application Area: Used in water-based cooling or washing processes. Suitable nozzles are used for water-based applications.

Types: Flat jet nozzles, round fan nozzles.

Features:*

Flow Rate: 1 L/min – 20 L/min.

Pressure: 3 bar – 5 bar (can be used for washing and cooling purposes).

Spray Type: Round cone, flat fan.

5. Liquid Distribution Nozzles

Application Area: Used for even distribution of chemicals, bleaches, or protective liquids onto the paper surface or production machines.

Types: Fine mist nozzles, full cone nozzles.

Features:*

Flow Rate: 1 L/min – 50 L/min (varies depending on the type of liquid).

Atomization: Fine atomization (more effective for chemical liquids).

Pressure: 3 bar – 7 bar.

Technical Specifications of Nozzles Used in the Paper Industry

1. Coating Nozzle:

* Exit Angle: 60° - 120° (common exit angles for wide areas).

* Droplet Size: 10 µm - 50 µm.

* Flow Rate: 1 L/min – 30 L/min.

* Operating Pressure: 2 bar – 6 bar.

* Material: Stainless steel, aluminum, plastic.

2. Cooling Nozzle:

* Liquid Intake Capacity: 0.5 L/min – 10 L/min.

* Atomization: Fine mist atomization (liquid is atomized into very small droplets).

* Temperature Resistance: Between -20°C and 80°C.

* Pressure: 3 bar – 8 bar.

* Material: Stainless steel, plastic.

3. Washing Nozzle:

* Flow Rate: 5 L/min – 50 L/min (adjustable according to washing efficiency).

* Pressure: 3 bar – 10 bar.

* Atomization Type: Fine mist or flat jet.

4. Liquid Distribution Nozzle:

* Flow Rate: 1 L/min – 50 L/min.

* Pressure: 3 bar – 7 bar.

* Spray Surface: Round cone, flat fan.

Important Factors for Nozzle Selection:

Atomization: Depending on the requirements of the application, the atomization type should be selected. Fine atomization is necessary, especially for surface coating and washing processes.

Spray Area: The exit angle of the nozzles should be selected depending on which area needs to be covered. Larger exit angles may be required for large areas.

Liquid Flow and Pressure: The flow rate and pressure of the nozzles should be adjusted according to the type and amount of liquid to be used in the spraying process.

Material Durability: The chemicals and temperatures used during paper production can affect the durability of the nozzles. Durable materials such as stainless steel are usually preferred.

Conclusion:

Nozzles used in the paper industry play an important role in every stage of production processes. Choosing the right nozzle in applications such as painting, cooling, washing, and liquid distribution increases efficiency and improves paper quality. Technical features such as atomization, flow rate, pressure are the basic factors that affect the performance of the nozzle used. Choosing the right nozzle helps optimize paper production processes and reduce costs.