Air-Water Nozzles: High Efficiency and Versatility in Industrial Applications

Air-Water Nozzles: High Efficiency and Versatility in Industrial Applications

Air-water nozzles provide high efficiency, low energy consumption, and effective liquid distribution in many industrial applications. These nozzles are especially critical in areas such as cooling, humidification, cleaning, washing, and chemical processes. They can be used in both high-pressure and low-pressure systems, and thanks to innovative designs and customizable features, they can be preferred in a wide range of applications. With developing technologies, air-water nozzles will become even more efficient and environmentally friendly in the future.

These advantages once again reveal the importance and versatility of air-water nozzles in industrial processes. Regardless of the sector in which they are used, air-water nozzles play an important role in reducing costs and increasing operational efficiency.

What is an Air-Water Nozzle?

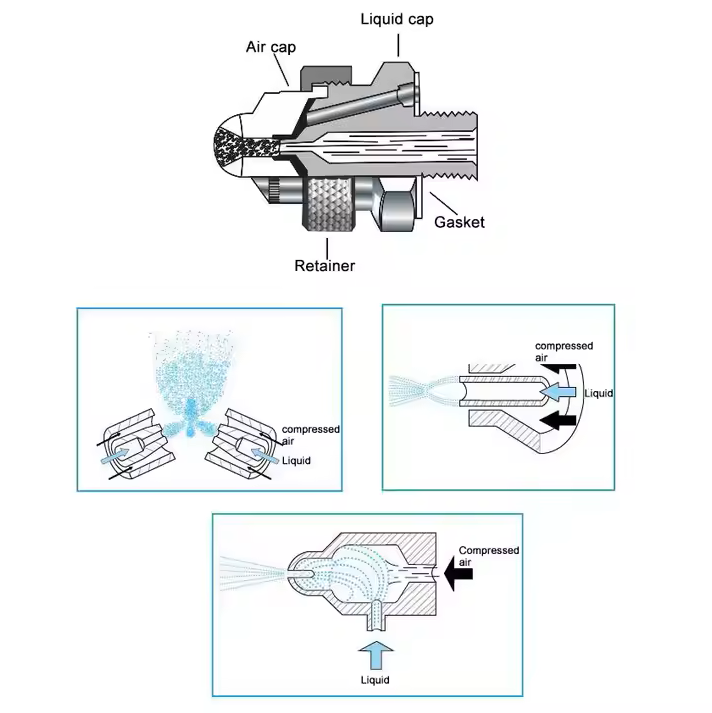

An air-water nozzle is a type of spray nozzle used to atomize liquids into fine droplets, especially in industrial applications. These nozzles enable the liquid to be converted into small droplets by using air and water together. Air allows the liquid to be distributed more efficiently and homogeneously, and is used in processes such as cooling, humidification, cleaning, and spray drying. Air-water nozzles are mostly used in various applications such as cooling systems, industrial cleaning, food processing, liquid distribution, and fire extinguishing.

Types of Air-Water Nozzles

Air-water nozzles are divided into several types with different working principles. Each type has its own advantages and usage areas.

Air-Water Atomization Nozzle:

Working Principle: Mixes water with air to atomize it. As the air pressure increases, the water is separated into finer droplets. It is mostly used in areas such as industrial cooling, humidification, and chemical spraying.

Usage Areas: Cooling towers, automotive industry, heating systems, food processing.

Air-Water Wash Nozzle:

Working Principle: Cleans surfaces and removes oils and dirt by using a mixture of high-pressure air and water. These nozzles are especially preferred in industrial cleaning.

Usage Areas: Automotive industry, machine washing, industrial cleaning.

Steam-Air-Water Nozzle:

Working Principle: These nozzles combine steam, air, and water to atomize the water for evaporation. It is especially preferred in applications requiring high temperatures.

Usage Areas: Food processing, disinfection, dry cleaning.

Technical Data and Numerical Information of Air-Water Nozzles

In order for air-water nozzles to operate efficiently, the correct technical specifications must be selected. Below are the basic numerical data and technical information to consider when choosing an air-water nozzle.

| Feature | Values |

| Nozzle Type |

Air-Water Atomization, Air-Water Wash, Steam-Air-Water Atomization

|

| Flow Rate Range |

0.1 L/min - 1000 L/min (varies depending on model and pressure)

|

| Operating Pressure |

2 bar - 80 bar (usually varies depending on application and nozzle type)

|

| Outlet Pressure |

2 bar - 25 bar (depends on nozzle type and operating conditions)

|

| Droplet Size |

10 - 120 microns (varies depending on flow rate and pressure)

|

| Outlet Angle |

30° - 120° (spread angle)

|

| Temperature Range |

-10°C to 200°C (varies depending on material type and usage conditions)

|

| Connection Type |

Threaded, flanged, quick-connect connection options

|

| Liquid Type |

Water, chemical liquids, oils, solvents

|

| Material Selection |

Stainless steel (SS304, SS316), copper, PVC, PTFE, aluminum

|

| Mounting Type |

Fixed, mobile, embedded mounting options

|

| Flow Rate Control |

Adjustable flow rate and pressure control

|

| Surface Coverage Area |

0.1 m² - 50 m² (spread area, varies depending on nozzle type)

|

Usage Areas of Air-Water Nozzles

Air-water nozzles offer a wide range of uses in different industrial applications:

Cooling Systems:

In industrial cooling applications, air-water nozzles atomize liquids into fine droplets, allowing heat to drop quickly. Cooling towers and mechanical cooling systems, in particular, use these nozzles.

Humidification:

For greenhouses, air humidification, and indoor environments, air-water nozzles increase the humidity level in the environment by adding moisture to the air.

Cleaning and Washing:

In high-pressure industrial cleaning applications, air-water nozzles provide effective cleaning. These nozzles are used especially in areas such as machine cleaning and the food processing industry.

Food Processing:

In food production lines, air-water nozzles are frequently used in vegetable and fruit washing, cooling, and disinfection processes.

Fire Extinguishing:

Air-water nozzles can also be used in fire extinguishing systems. Fire extinguishing processes are accelerated and become more efficient with high-efficiency water atomization.

Advantages of Air-Water Nozzles

Efficient Liquid Distribution:

The combination of air and water allows liquids to be atomized into finer droplets, which helps them spread evenly over a wider area.

Energy Saving:

Fine droplets evaporate faster, which reduces energy consumption and increases process efficiency.

Wide Application Area:

Air-water nozzles provide versatility as they can be used in different industrial applications. It is preferred in a wide area such as industrial cooling, cleaning, painting, and fire extinguishing.

More Effective Cooling and Humidification:

As water evaporation accelerates, the temperature control of the environment is made more effective and humidity levels can be adjusted.

Things to Consider in Air-Water Nozzles

Pressure and Flow Rate Selection: It is important to determine the correct pressure and flow rate values during nozzle selection. High pressure provides finer droplets.

Liquid Type and Usage Conditions: The type of liquid to be used, its chemical properties and temperature range will affect the material selection of the nozzles.

Connection Type: The appropriate connection type should be selected for nozzle installation (threaded, flanged, etc.).

Maintenance and Cleaning: Regular maintenance and cleaning ensure that the nozzles have a long life and prevent performance degradation.

Conclusion

Air-water nozzles are important devices used in versatile industrial applications, atomizing liquids into fine droplets and increasing process efficiency. It is very useful in areas such as cooling, cleaning, food processing, and fire extinguishing. The correct selection of technical data and appropriate nozzles greatly increases system efficiency and application success.

If you would like to get more information or detailed information about a specific model, you can contact air-water nozzle manufacturers and suppliers. These nozzles can be supplied in properties suitable for your industrial needs and in various technical parameters.