Tank Washing Nozzle

Tank Cleaning Nozzles

Tank cleaning nozzles are specialized nozzles used for cleaning large tanks, storage silos, and other enclosed spaces. These nozzles distribute liquids evenly across the entire surface of the tank, making cleaning efficient. They are commonly used in the food, chemical, pharmaceutical, and petroleum industries. Tank cleaning nozzles typically spray liquid to clean a specific area or the entire interior of a tank.

| Feature | Values |

| Nozzle Type |

360° rotary nozzle, fixed nozzle, high-pressure nozzle

|

| Operating Pressure |

3 bar - 12 bar (typically 4 bar - 8 bar)

|

| Flow Rate |

20 L/min - 400 L/min (depending on nozzle type and application conditions)

|

| Spray Angle |

30° - 90° (varies by nozzle type, typically 360° for rotary nozzles)

|

| Droplet Size |

100 - 500 microns (depends on liquid and pressure)

|

| Temperature Range |

-10°C to 150°C (depends on material and application)

|

| Material Selection |

Stainless steel (SS304, SS316), PVC, PP, PTFE, aluminum

|

| Connection Type |

Flanged, threaded, clamped (typically industrial connections)

|

| Cleaning Area |

20 m² - 60 m² (depends on nozzle type and tank size)

|

| Liquid Type |

Water, water-based solutions, chemical liquids, acidic liquids

|

| Operating Time |

Continuous operation or intermittent rotary motion

|

Operating Principle and General Structure

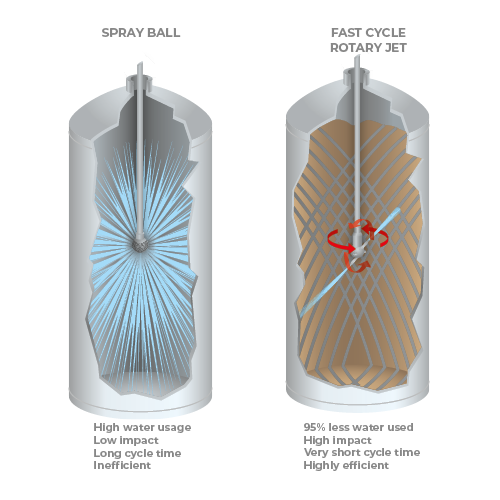

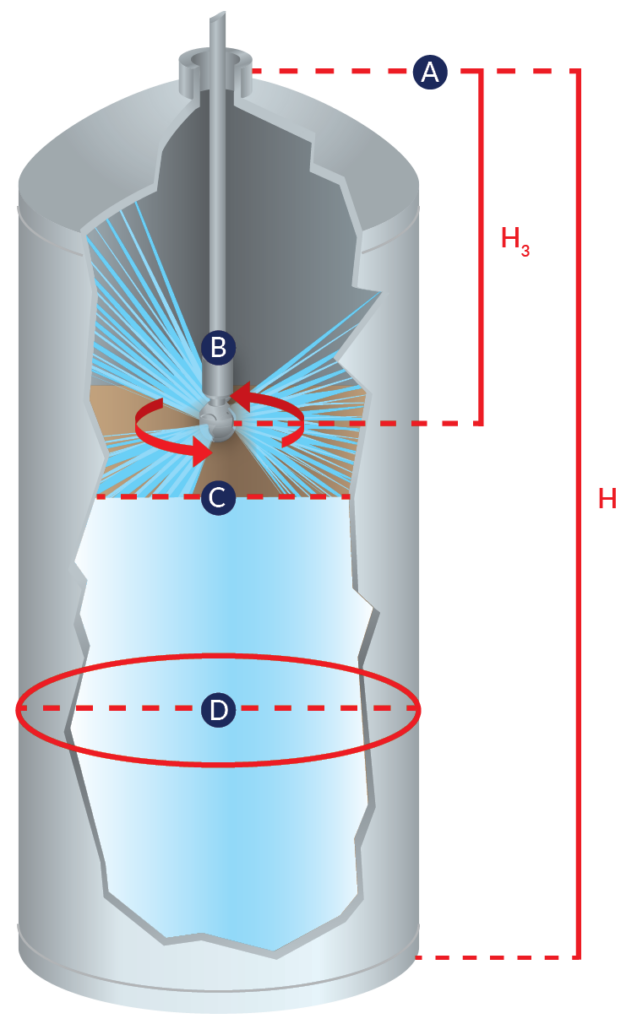

Tank cleaning nozzles can be rotary, fixed, or driven. Rotary nozzles clean the entire inner surface of the tank by rotating. Fixed nozzles spray liquid at a fixed angle, while high-pressure nozzles use high-pressure jets for cleaning.

Rotary Nozzles: Most commonly rotate 360 degrees, cleaning the entire inner surface of the tank.

High-Pressure Nozzles: Operate at pressures between 3 and 12 bar, providing a powerful jet for cleaning.

Advantages of Tank Cleaning Nozzles

Efficient Cleaning: 360-degree rotary nozzles clean the entire tank surface, providing a thorough clean.

Time Savings: High-pressure nozzles remove stubborn dirt faster, reducing cleaning time.

Even Liquid Distribution: Liquid is evenly distributed across the tank surface, ensuring a consistent clean.

Chemical Compatibility: Nozzles made of various materials can handle acidic or basic solutions.

Low Water Consumption: Efficient use of liquid minimizes consumption.

Types of Tank Cleaning Nozzles and Applications

360° Rotary Tank Cleaning Nozzles:

Operating Principle: Rotates to spray liquid across the entire tank.

Application: Petroleum, chemical, and oil tanks.

Features: Suitable for large and medium-sized tanks.

High-Pressure Nozzles:

Operating Principle: High-pressure jet for removing stubborn dirt.

Application: Dirty tanks, industrial cleaning, oily tanks.

Features: Effective for tough cleaning tasks.

Fixed Nozzles:

Operating Principle: Fixed spray angle for cleaning specific areas.

Application: Food industry, milk tanks, large storage areas.

Features: Effective for cleaning large surface areas.

Low-Pressure Nozzles:

Operating Principle: Low-pressure spray for gentle cleaning.

Application: Food industry, fruit and vegetable washing, food processing plants.

Features: Minimizes liquid consumption.

Material Selection for Tank Cleaning Nozzles

Stainless Steel (SS304, SS316): Resistant to chemicals, high temperatures, and wear. Suitable for acidic and basic environments.

PVC, PP, PTFE: Lower cost alternatives, resistant to chemicals. Suitable for lower temperature and pressure applications.

Aluminum: Lightweight and cost-effective, but limited chemical resistance.

Selecting a Tank Cleaning Nozzle

Factors to consider when selecting a nozzle include:

Tank Size: Larger tanks require rotary or high-flow nozzles, while smaller tanks may use fixed nozzles.

Liquid Type: Chemical compatibility is essential.

Operating Pressure and Temperature: The nozzle must withstand the operating conditions.

Flow Rate: The required flow rate depends on the cleaning task and tank size.

Conclusion

Tank cleaning nozzles play a crucial role in industrial cleaning applications. By choosing the right nozzle based on specific requirements, it is possible to achieve efficient and thorough cleaning while minimizing downtime and costs.