Spray Nozzles in the Food and Beverage Industry

The food and beverage industry is one of the sectors where hygienic and efficient production processes are paramount. The equipment used in this industry directly affects the quality, safety, and processing speed of products. Spray nozzles enable the accurate distribution of liquids, the uniform treatment of product surfaces, the efficiency of cooling processes, and the maintenance of general hygiene conditions in this industry. In this article, comprehensive information about the usage areas and advantages of spray nozzles commonly used in the food and beverage industry will be presented.

1. Usage Areas in Food Production

a. Surface Cleaning and Hygiene

Hygiene in food production lines plays a critical role in maintaining product quality. Spray nozzles are used to clean equipment, machinery, and transport lines during production. High-pressure water nozzles allow cleaning solutions to be quickly spread over large surfaces. This is extremely important for preventing bacterial contamination and accelerating cleaning processes in food processing areas.

Usage Areas:

Machines and Production Line Cleaning

Transport Wheels and Conveyors

Surface Cleaning

Features:

Spray Angle: 90° - 120°

Flow Capacity: 5 L/min - 50 L/min

Droplet Size: 30 - 70 microns

b. Liquid Coating and Spraying

Flat fan nozzles or round atomizer nozzles are used to coat food products with liquid (oil, vinegar, syrups, or other protective solutions). These nozzles spray liquids thinly and evenly onto the product surface, ensuring that coating processes are smooth and homogeneous. These types of coatings can be done to extend the shelf life of food products or to improve the flavor of the products.

Usage Areas:

Coating Snacks, Biscuits, and Chips: Applying oil or spices to the outer surface of products.

Confectionery and Chocolate Products: Evenly distributing sugary liquids.

Protective Layers: Spraying protective liquids onto food items.

Features:

Spray Angle: 30° - 90°

Flow Rate: 10 L/min - 100 L/min

Droplet Size: 50 - 100 microns

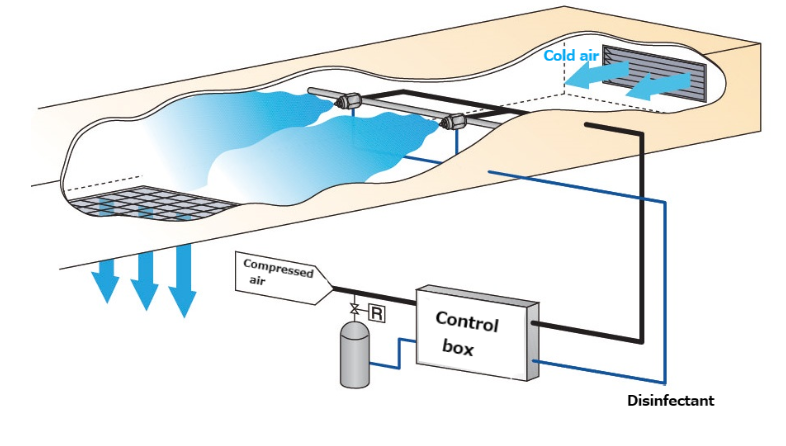

c. Cooling

In the food processing industry, especially in the production of meat, fish, and dairy products, it is necessary to control the temperatures of the products and cool them quickly. Cooling nozzles atomize water into fine droplets, allowing hot food products to be cooled rapidly. This is critical to ensure that products remain fresh and of high quality.

Usage Areas:

Meat and Fish Cooling: Quickly cooling products after production.

Dairy Products: Rapidly cooling hot dairy products during milk processing.

Features:

Spray Angle: 90° - 120°

Droplet Size: 50 - 80 microns

Flow Rate: 10 L/min - 50 L/min

d. Drying with Liquid Spraying

During the processing of some food products, it may be necessary to evaporate or dry liquids. Liquid atomization allows this process to take place more quickly and effectively. For example, in the production of powdered food products (milk powder, spices, etc.), spray nozzles create suitable conditions for the drying process by separating the liquid into fine droplets.

Usage Areas:

Milk Powder Production: Turning liquid milk products into powder with a spray drying system.

Spice Drying: Quickly removing the moisture from spices and processing the product in dry form.

Features:

Spray Angle: 20° - 90°

Droplet Size: 10 - 50 microns

Flow Rate: 15 L/min - 150 L/min

2. Usage Areas in Beverage Production

a. Bottle Washing and Sterilization

In beverage production facilities, cleaning and sterilizing bottles and other packaging is critical. High-pressure spray nozzles ensure that bottle surfaces are cleaned and disinfected properly. These nozzles provide effective cleaning inside and outside the bottles, thus creating a hygienic production environment.

Usage Areas:

Bottle Washing: Cleaning beverage bottles.

Packaging Sterilization: Disinfecting plastic, glass, or metal bottles and cans.

Features:

Spray Angle: 45° - 90°

Flow Rate: 20 L/min - 100 L/min

Droplet Size: 40 - 80 microns

b. Wine and Alcoholic Beverage Capping

During the bottling of wine and other alcoholic beverages, appropriate protective coatings can be applied to the surfaces of the liquids to preserve the quality of the beverage. Spray nozzles reduce the risk of oxidation and maintain the freshness of the beverage by applying a thin protective layer around the bottle opening.

Usage Areas:

Wine Bottle Capping: Spraying capping materials around the bottle opening.

Features:

Spray Angle: 30° - 60°

Droplet Size: 20 - 40 microns

Flow Rate: 5 L/min - 20 L/min

c. Beverage Mixtures and Aroma Application

In beverage production, especially in fruit juice, soda, and other non-alcoholic beverages, aroma spray nozzles are used to ensure that the beverage is mixed homogeneously. These nozzles help to distribute the aromas evenly while providing the mixing of liquids.

Usage Areas:

Spraying Aroma and Sugary Liquid: In beverage mixtures, especially in the addition of fruit juices, sweeteners, or sugary liquids, a homogeneous distribution is achieved.

Mixing in Carbonated Beverages: In the production of soda or carbonated beverages, it is used to properly distribute gaseous components and ensure a homogeneous mixture of the beverage.

Features:

Spray Angle: 30° - 90°

Droplet Size: 20 - 40 microns

Flow Rate: 10 L/min - 50 L/min

3. Advantages of Spray Nozzles in the Food and Beverage Industry

a. Efficient Water Usage

Spray nozzles offer the possibility of irrigating or cleaning larger areas with less water by atomizing the water evenly. This provides an important advantage, especially in regions where water is scarce or when environmental sustainability is at the forefront. At the same time, this helps to reduce production costs.

b. Faster Production Processes

Spray nozzles accelerate production processes by allowing liquids to spread quickly and efficiently. For example, in food and beverage production, rapid cooling of products, bottle cleaning, and surface coating processes can be done in a shorter time.

c. Homogeneous Distribution

Spray nozzles ensure that liquids are distributed homogeneously over surfaces by atomizing liquids into fine droplets. This feature is of great importance especially in the coating of food products, bottle cleaning, and aroma applications. Homogeneous distribution increases product quality and ensures that the desired result is achieved.

d. Energy and Time Savings

Since spray nozzles operate with high efficiency, they usually require less energy and time to be spent. This helps businesses reduce their production costs.

e. Hygienic Production Conditions

Spray nozzles help maintain hygienic conditions by allowing liquid to spread quickly over large surfaces. It is especially important to carry out cleaning and disinfection processes effectively in food processing lines. Spray nozzles facilitate these processes and ensure food safety.

Conclusion

In the food and beverage industry, the use of s offers many advantages, from efficient production processes to high product quality. Spray nozzles used in critical applications such as ensuring hygienic conditions, liquid coating and spraying processes, cooling and drying are indispensable equipment of the industry. Different application areas and various designs of nozzles allow effective results to be obtained in all kinds of food and beverage production.

Choosing the right type of spray nozzle is important to increase the efficiency of production processes, save water, and improve the quality of the final product. This technology in the food and beverage sector is becoming even more efficient with new designs and features that are developing over time.