Hollow cone Nozzle

Hollow Cone Nozzle and Working Principle

In industrial applications, spray nozzles are designed to meet different needs. One of the most commonly used types is the hollow cone nozzle, which creates fine droplets and covers a wide surface area. Thanks to these features, it is widely used in cooling, humidification, and cleaning processes. In this article, we will explore the definition, working principle, advantages, and applications of hollow cone nozzles in detail.

What is a Hollow Cone Nozzle?

A hollow cone nozzle is a type of spray nozzle that produces a hollow, cone-shaped spray pattern. In other words, the spray forms a circular ring, leaving the center empty.

Key characteristics:

-

Provides fine atomization even at low flow rates.

-

Produces small droplet sizes for effective surface coverage.

-

Ideal for precision spraying applications.

They are typically made of stainless steel or ceramic materials. Ceramic orifice models are especially popular due to their excellent wear resistance and long service life.

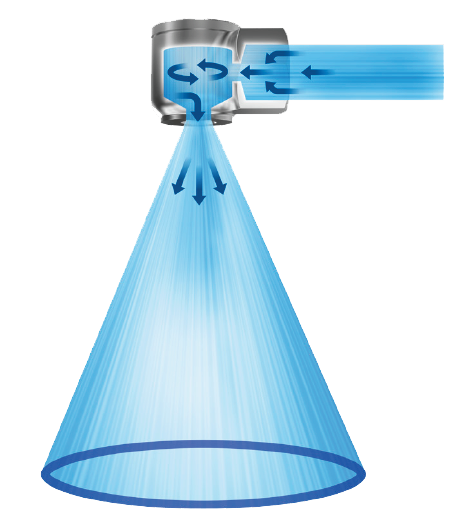

Working Principle of Hollow Cone Nozzles

The working principle of hollow cone nozzles is based on directing liquid into a specially designed swirl chamber.

-

The liquid enters the nozzle under inlet pressure.

-

Inside the nozzle, a spiral or swirl chamber forces the liquid to rotate.

-

The rotational motion causes the liquid to exit the nozzle at high velocity, creating a hollow cone spray pattern.

As a result, the liquid is atomized into fine droplets and evenly distributed in a ring-shaped spray.

Advantages of Hollow Cone Nozzles

-

✅ Fine spray pattern: Ensures uniform distribution with small droplet sizes.

-

✅ Efficient cooling: Large heat transfer surface area enables rapid cooling.

-

✅ Effective at low flow rates: Covers wide areas with minimal liquid use.

-

✅ Durability: Stainless steel and ceramic construction ensure longer lifespan.

Applications of Hollow Cone Nozzles

Hollow cone nozzles are widely used across different industries:

-

Tags:

Share: