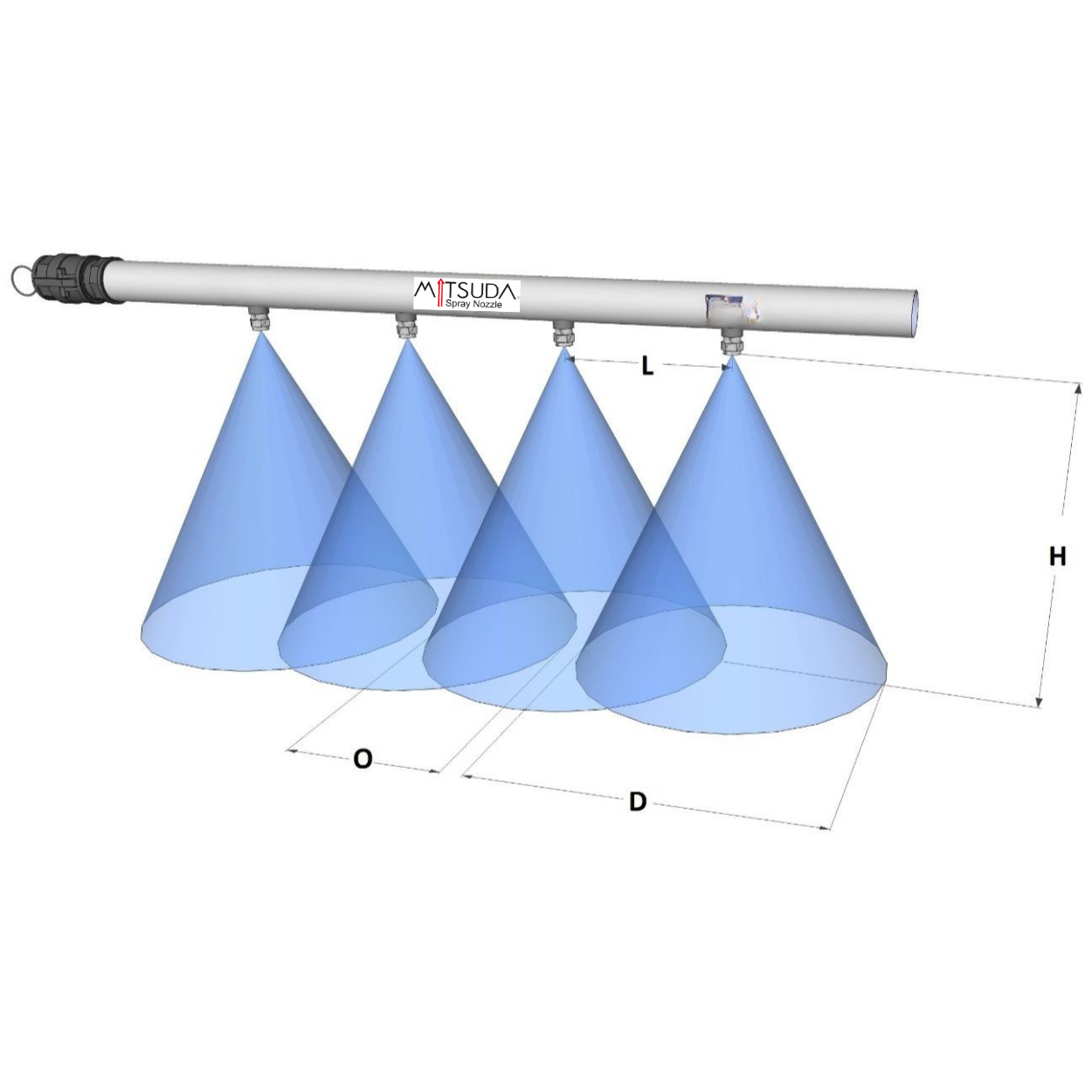

Full Cone Nozzle

As the name suggests, full cone nozzles have a cone-shaped spray pattern that covers the entire surface inside the cone. You can find our nozzles here.

Full cone nozzles are widely used in various industries for applications like washing, cooling, and fire suppression. They produce a solid, cone-shaped spray pattern with a uniform distribution of droplets.

Here's a simplified explanation of how they work:

Internal Structure:

Inlet: The liquid enters the nozzle through the inlet.

Swirl Chamber: The liquid is directed into a chamber where it undergoes a swirling motion. This swirling action is crucial for creating the cone-shaped spray pattern.

Orifice: The swirling liquid exits the nozzle through a small opening called the orifice.

Spray Pattern Formation:

As the liquid exits the orifice, the centrifugal force from the swirling motion causes it to spread out in a conical shape.

The size and angle of the cone can be adjusted by changing the design of the swirl chamber and the size of the orifice.

Visual Representation:

full cone nozzle with a cutaway view showing the internal components and the spray pattern

Key Points:

Uniform Distribution: The swirling action ensures that the liquid is distributed evenly across the entire cone.

Adjustable Spray Angle: The angle of the spray can be adjusted by changing the nozzle design.

Versatility: Full cone nozzles can be used for a wide range of applications due to their adjustable spray patterns and ability to handle various liquids.

Full Cone Nozzle: A Comprehensive Guide

1. Operating Principle

A Full Cone Nozzle disperses a liquid in a conical spray pattern, typically covering a 360-degree area. This is achieved by the liquid flowing through an orifice at the tip of the nozzle, breaking into small droplets and spreading across a wide surface.

| Feature | Values |

| Nozzle Type |

Full Cone Nozzle

|

| Droplet Size |

20-200 microns (varies based on nozzle)

|

| Operating Pressure |

1 bar to 50 bar (varies based on model and application)

|

| Flow Rate |

0.1 L/min to 1000 L/min (varies based on model and application)

|

| Spray Pattern |

Full cone spray pattern (360°)

|

| Spray Angle |

60° to 120° (90° is most common)

|

| Nozzle Material |

Stainless steel, brass, plastic (PVC, PVDF, PTFE, etc.), ceramic, etc.

|

| Connection Type |

Threaded connection, flange connection, industrial connection types

|

| Operating Temperature |

-20°C to 150°C (varies based on material)

|

| Corrosion Resistance |

High (especially stainless steel or plastic models)

|

3. Calculation of Flow Rate

The flow rate of a full cone nozzle can be calculated using the following formula:

Q = C_d * A * √(2ΔP/ρ)

Where:

Q = Flow rate (m³/s)

C_d = Discharge coefficient (varies based on nozzle type and size, typically around 0.9)

A = Nozzle outlet area (m²)

ΔP = Pressure difference (Pa)

ρ = Density of the fluid (kg/m³)

Droplet Size:

Droplet size is primarily influenced by the fluid's viscosity and operating pressure. Full cone nozzles typically produce droplets in the 20-200 micron range. This affects the spray's coverage and effectiveness on the target surface.

Spray Angle:

The spray angle of full cone nozzles usually ranges from 60° to 120°. A 90° angle is the most common for industrial applications. Wider angles (110° to 120°) are used when a broader coverage is required.

4. Advantages

Uniform Distribution: Full cone nozzles provide a uniform distribution of liquid over a wide area, ensuring effective mixing or cooling.

High Droplet Dispersion: Breaking the liquid into small droplets enhances surface interaction and often leads to faster reactions.

Versatility: Suitable for a wide range of fluids and applications, capable of dispersing mixtures of liquids, gases, and sometimes solids.

Energy Efficiency: Effective distribution even at lower pressures, resulting in energy savings.

Durability: Resistant to corrosion with options like stainless steel and plastic materials.

5. Applications

Cooling Systems: Used in industrial cooling towers for uniform liquid distribution.

Chemical Production: Used to accelerate chemical reactions or distribute chemicals evenly.

Cleaning and Washing: Employed for effective cleaning of large areas in industrial applications.

Agriculture and Fertilization: Used to distribute water or fertilizers evenly over large fields.

Evaporation and Heating: Increases surface area of liquids for evaporation or heat transfer.

6. Material Selection and Durability

Common materials for full cone nozzles include:

Stainless Steel (SS 304, SS 316): Corrosion-resistant and chemically inert, suitable for high temperature and pressure conditions.

Plastic (PVC, PVDF, PTFE): High chemical resistance and cost-effective, suitable for lighter applications.

Ceramic: Ideal for highly abrasive fluids.

7. Sizing and Selection

When sizing a nozzle, consider the following parameters:

Flow Rate: Required liquid volume (L/min or L/h)

Pressure: Pressure needed to achieve the desired droplet size and spray angle.

Spray Area: Size of the area to be covered affects the nozzle's spray angle.

By optimizing these parameters, the most suitable full cone nozzle can be selected for maximum efficiency.

Conclusion

Full Cone Nozzles are essential equipment for efficient liquid distribution in various industrial applications. The correct nozzle selection, based on specific application requirements, ensures optimal performance and energy efficiency.

nozzle