Choosing an air nozzle

Choosing an air nozzle is a process that requires making the right choice according to the type of application, operating conditions, and desired performance characteristics. The correct air nozzle selection is critical to increase efficiency, achieve the desired results, and save energy. Here are some factors to consider when choosing an air nozzle:

1. Application Type

Cleaning and Washing: If air nozzles are used to clean equipment, surfaces, and vehicles, nozzles with a wide spray angle and high flow rate are generally preferred. When it is necessary to spray water or air at high pressure, nozzle options that provide a strong air flow should be preferred.

Cooling and Ventilation: If an air nozzle is used for cooling or ventilation purposes, nozzles with low pressure, large diameter, and higher air flow are generally preferred.

Industrial Processes: Especially in industrial areas such as metal processing and plastic production, nozzles with a sharp and intense air flow can be selected.

2. Air Flow and Pressure

Air Flow: When choosing an air nozzle, it is very important to determine the required air flow. The flow is usually measured in L/min (liters/minute). The amount of this flow should be determined according to the type of application. For example, a nozzle with a higher flow rate may be required to quickly clean a large area for cleaning purposes.

Pressure: Pressure determines the power of the air flow. High pressure is necessary to effectively clean or process a specific area. However, high pressure also means more energy consumption. The pressure measured in bar should also be taken into account.

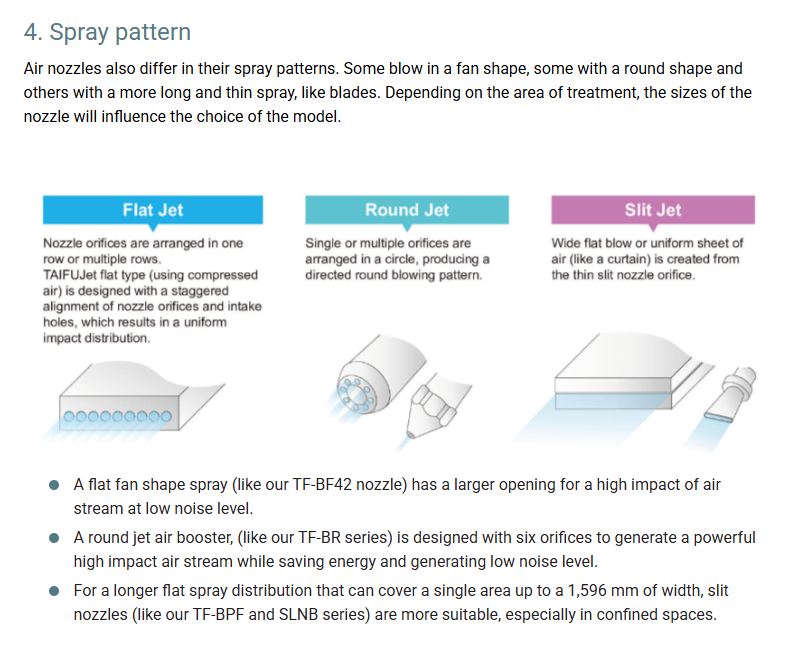

3. Spray Pattern

Air nozzles can have different spray patterns. There are various spray patterns such as flat fan, round, hollow cone, and full cone.

Flat Fan Spray: It is preferred to spread liquid or air widely over surfaces.

Round or Cone Spray: Conical and round patterns provide a dense effect by targeting a narrower area, so they may be suitable for precise operations.

4. Material and Durability

The material used in the production of the air nozzle is important depending on the conditions of the environment used:

Stainless Steel Nozzles: They are resistant to corrosion, so they are preferred in harsh conditions such as acidic or alkaline environments.

Plastic Nozzles: They are generally light and low cost, and are used in less challenging conditions.

Bronze or Copper Alloy Nozzles: They are resistant to high temperatures and can be used in extreme heat or high temperature applications.

5. Droplet Size

The droplet size formed by the sprayed air may vary depending on the purpose of the application:

Fine Droplets: Fine droplets allow water or liquid to spread over a wider area, and are usually preferred in cooling and humidification applications.

Large Droplets: Large droplets are ideal for cleaning and intensive spraying applications.

6. Spray Distance and Area

When choosing an air nozzle, it is important to consider from which distance you will make an effective spray. For example:

Short Distance: Powerful air nozzles can be preferred to provide a more intense air flow and effect at a low distance.

Long Distance: Nozzles that will affect a long distance provide an air flow that spreads over large areas by spraying at a lower density.

7. Efficiency and Energy Consumption

Saving energy is important, especially in long-term use. High-efficiency air nozzles have suitable designs to save energy. In addition, nozzles with the correct air pressure and flow rate operate more efficiently by reducing energy loss.

8. Operating Conditions

When choosing an air nozzle, environmental conditions should also be considered:

Temperature: High temperatures can affect the durability of the material and the performance of the nozzles.

Chemical Environments: The nozzles to be used in acidic or alkaline environments must be made of materials that are resistant to these conditions.

Humidity: In highly humid environments, nozzles made of stainless steel or with special protective coatings can be preferred.

---

Conclusion

The selection of an air nozzle should be done carefully according to the purpose of the application, environmental conditions, and performance requirements. Choosing the right air nozzle can increase efficiency, reduce energy consumption, and improve the effectiveness of the application process. In any air nozzle selection, factors such as spray pattern, flow capacity, pressure, and material used should be considered.